Advanced membranes for CO2 capture: recent Sotacarbo results now published

Capturing carbon dioxide (CO2) produced by power generation and industrial plants is today fully feasible from the technical point of view, but it is still quite expensive. Currently, the only

Date:

30 March 2020

Capturing carbon dioxide (CO2) produced by power generation and industrial plants is today fully feasible from the technical point of view, but it is still quite expensive. Currently, the only technology available for large-scale application is chemical absorption, where the CO2-rich gas is washed by means of a regenerable amine-based aqueous solution. But the use of this kind of solvent involves a high energy consumption for the thermal regeneration phase and a series of environmental and operation issues (due, for example, to the high corrosivity of the solvent), which still entails high operation costs.

One of the most promising solutions to this problem is represented by CO2 capture with membranes, which separate carbon dioxide from a gas mixture thanks to a wide series of chemical and physical mechanisms that make the material permeable to some species and impermeable to the other ones. With respect to amine-base solvents, membrane separation is conceptually easier and simpler to be managed, it doesn’t involve any corrosion issues and the environmental risks are not significant. However, the technology not yet raised to maturity for large-scale commercial applications in CO2 capture sector.

In this field, Sotacarbo is collaborating for several years with the University of Bologna (Department of Civil, Chemical, Environmental and Materials Engineering) for the development of advanced membranes for CO2 capture, with the aim to improve permeability and selectivity of the materials, making them more efficient and competitive.

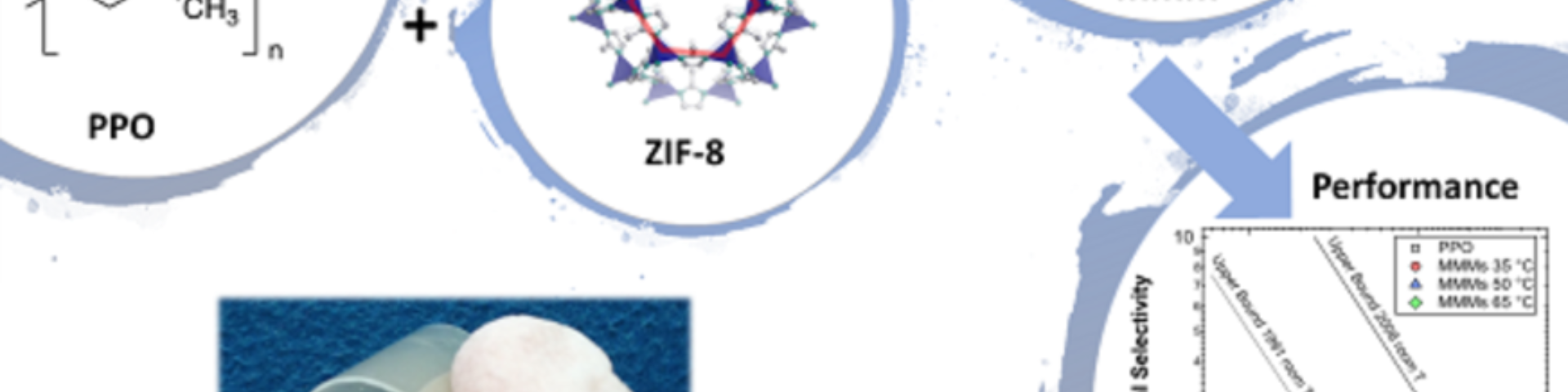

And the recent results of this research have been now published by the open-source international journal Membranes (edited by MDPI). The work – that also includes the participation of the Massachusetts Institute of Technology (MIT) – is focused on the development and characterization of glassy PPO (poly(2,6-dimethyl-1,4-phenylene oxide)) membranes and on the benefits obtained adding a specific zeolite (ZIF-8), which operates as a molecular sieve increasing selectivity up to 800%.

The paper – titled “Enhancing the Separation Performance of Glassy PPO with the Addition of a Molecular Sieve (ZIF-8): Gas Transport at Various Temperatures” (authors: Francesco Maria Benedetti, Maria Grazia De Angelis, Micaela Degli Esposti, Paola Fabbri, Alice Masili, Alessandro Orsini e Alberto Pettinau) – has been developed within the “Centre of Excellence on Clean Energy” (CEEP), research and development project managed by Sotacarbo and funded by the Regional Government of Sardinia. APettinau

Last update

16/05/2023, 13:44