Development of electrochemical processes for the reuse of CO2

CEEP (Centro Eccellenza sull’Energia Pulita - Clean Energy Centre of Excellence) research activities in the field of carbon dioxide reuse technologies.

Date:

30 September 2021

Despite growing interest, CO2 reuse technologies for the production of fuels through electrochemical and photoelectrochemical (PEC) processes are still far from a possible commercial application. In recent years Sotacarbo has developed expertise in the experimental characterization of electrode type materials in collaboration with the Department of Mechanical, Chemical and Materials Engineering (DIMCM) of the University of Cagliari, the main scientific partner.

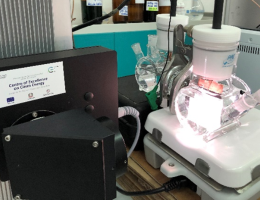

The process consists of direct conversion of carbon dioxide (by reaction with hydrogen from renewable sources) into fuels or chemical compounds (depending on process conditions). Unlike conventional catalytic conversion-based processes, the PEC reduction process takes place within an electrochemical cell, with part of the activation energy required for the reaction to proceed supplied directly by sunlight. The main objective of the study is to gain further knowledge of photoelectrochemical carbon dioxide reduction technologies by selecting the most appropriate electrode configurations on which yield and selectivity towards the desired products are maximized. In particular, an electrochemical reactor has been designed with a configuration called “photoanode-driven photoelectrochemical system”, in which the reduction of CO2 at the cathode and the evolution of oxygen at the photoanode take place. For the latter, the behavior of nanotubular titanium dioxide structures synthesized in the laboratory and subsequently coupled with electrochemically deposited tungsten oxide was studied. The cathode process was instead studied using different electrodes such as boron-doped diamond (BDD). Studying the process and understanding the reaction mechanism is quite complicated, especially concerning the selectivity of the process towards the products of interest. In the meantime, a new electrochemistry laboratory has been set up at Sotacarbo Research Centre where, in addition to the photoelectrochemical (PEC) and the solar simulator, a whole series of equipment has been installed to monitor the process.

The margins for optimizing the process are still very wide, and preliminary contacts are being made with international partners for possible collaborations.

Various electrochemical techniques, both DC and AC, were used to obtain process information. In particular, cyclic voltammetry, linear sweep voltammetry and electrochemical impedance spectroscopy (EIS) were performed. Based on experimental results, a mathematical model of the process was implemented in order to quantify the effect of the operating parameters on the reaction and its products. The results will allow optimization of both the cell configuration and the applied potential or current values.

The future of the activity entails further process development, and the creation of a specific laboratory dedicated to the electrochemical production of hydrogen from renewable energy sources.

Last update

06/11/2024, 12:03